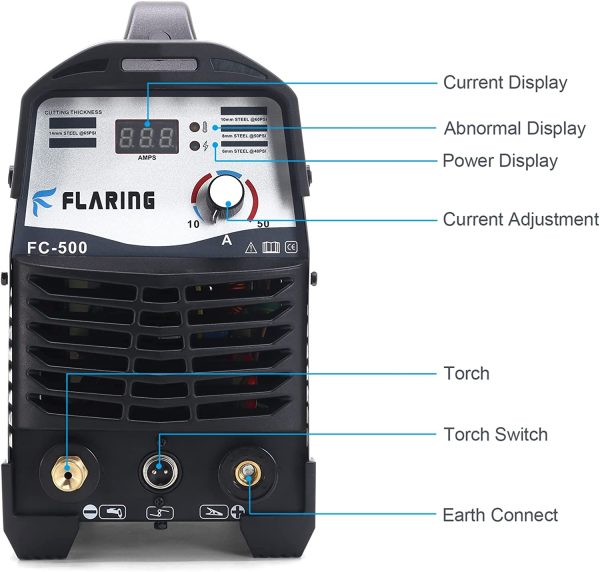

FLARING Plasma Cutter Equipment 50 AMP 220V IGBT 1/2” Clean Cut CUT50 Max 3/5‘’ Cut High Frequency Inverter Plasma Cutting Machine for Car Frame,Carbon Steel,Stainless Steel,Thin Copper,Aluminum

- Home

- Shop

- Equipments, Welding, Stick Welders

- FLARING Plasma Cutter Equipment 50 AMP 220V IGBT 1/2” Clean Cut CUT50 Max 3/5‘’ Cut High Frequency Inverter Plasma Cutting Machine for Car Frame,Carbon Steel,Stainless Steel,Thin Copper,Aluminum

FLARING Plasma Cutter Equipment 50 AMP 220V IGBT 1/2” Clean Cut CUT50 Max 3/5‘’ Cut High Frequency Inverter Plasma Cutting Machine for Car Frame,Carbon Steel,Stainless Steel,Thin Copper,Aluminum

$179.99

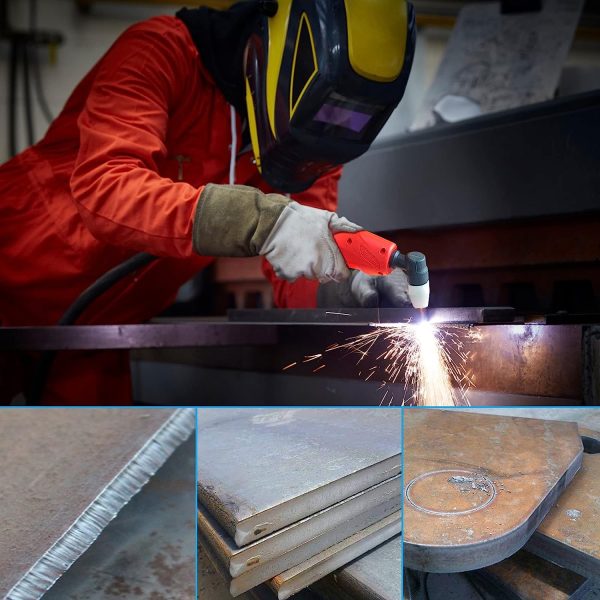

- [Cutting Ability] This plasma cutter machine automatic 220v(50/60hz),10-50A dc output, 1/2″(12mm) ideal clean cut and 3/5″(15mm) maximum severance cut under 220v,70% duty cycle. The upgraded model only supports 220v voltage input.

- [Cutting Material] Compact plasma cutter has a handle for portability and uses non-hazardous compressed air to cut stainless steel, alloy steel, mild steel, copper,cast iron,chrome and aluminum(Aluminum≤1/4″,Copper≤1/5″)

- [Breaker Recommendation] We suggest a 30A breaker on 220V while using this plasma cutter.Air Pressure 60-70PSI suggested.Btw,this CUT50 plasma cutting machine works well with a generator above 5000W.

- [Fan-Runs-on-Demand cooling system]The new machine uses powerful cooling system, “dormant” fan,only operates when needed. This cuts down on fan noise, along with reducing power consumption and contaminants drawn into the machine.

- [Warranty Assurance] We are a manufactory with over 10 years’ experience of professionals producing the plasma cutter machines,3 year’s warranty.Please add to cart and take it without hesitation

- Description

- Additional information

- Reviews (0)

Description

How a plasma cutter works?

What is Plasma?

Plasma cutters work by sending an electric arc through a gas that is passing through a constricted opening. The gas can be shop air, nitrogen, argon, oxygen. etc. This elevates the temperature of the gas to the point that it enters a 4th state of matter. Scientists call this additional state plasma. As the metal being cut is part of the circuit, the electrical conductivity of the plasma causes the arc to transfer to the work.

How does it work?

The plasma arc formation begins when gas is forced through a small nozzle orifice inside the torch. An electric arc generated from the external power supply is then introduced to this high pressured gas flow, resulting in what is commonly referred to as a “plasma jet”. It immediately reaches up to 40,000° F, quickly piercing through the work piece and blowing away the molten material.

About the Air Compressor

FLARING plasma cutters need compressed air to create the plasma.

After-sales Service

- FLARING provides 3-years of product quality service.

- Failures other than the machine case can be replaced within 30 days if you have a problem with the machines.

- Local support is available for all of our customers.

How to use the plasma cutter machine?

1. Check the package

1. pressure connector, 2. raw tape, 3. consumables, 4. pressure holder, 5. pt31 torch, 6. FC-500,

7. air regulator, 8. ground clamp, 9. hose, 10. hose clamp,

Please get supports in time if anything missed.

2. Connection 1

- Connect the pt31 torch

- Connect the ground clamp

- Refer the user manual

3. Connection 2

- Connect the air compressor

- Connect the air regulator

- Refer the user manual

4. Set the current

- Clamp the metal with ground clamp

- Power on the FC-500D

- Set the current

- Start cutting

What FLARING Provides?

Sales Service

- A 3-year service is provided for all the machines.

- Failures other than the machine case can be replaced within 30 days if you have a problem with the machines.

- Local support is available for replacement,repair etc.

What are the advantages?

- 4 IGBT, stable and powerful.

- industrial cooling fan,to improve the duty cycle.

- 4 rectifiers, 3 high-power large capacitors, making the machine more stable.

- The main transformer of all copper, the power is larger.

Why excellent cutting ability?

- 220V input voltage and 50A output current are the best match.FC500 is very suitable for home or small business projects !

- Cutting speed can reach 8000mm/min. The cutting speed needs to be determined according to the thickness and texture of the cut sheet.Cutting thick plates requires reduced movement speed.

- It is recommended to use 60-70PSI(about 0.4Mpa) air pressure.

Plasma Cutter Consumables

- To ensure that you can quickly use the machine.

- please find the buyer support after you got the FC-500 plasma cutter and get the consumables.

- 40pcs as shown up in the picture

Manufacture Testing

- Accurate Test: continuing to provide high current to ensure that each machine can bear still can stabilize output

- Simulation Test: undergoes 30 minutes of simulation work, easily cope with voltage fluctuations

- Manual Test: achieve easy arc, continuous arcing

High frequency transformer

- The FC-500D plasma cutting machine comes with 220V voltage

- IGBT inverter technology (the inverter frequency range is from 25-50KHz) to convert 50/60Hz alternating current (AC) to direct current (DC) and then to high frequency and lower voltage rectification.

- Attention:it is recommended to use a circuit breaker above 40A for 220V.

Certifications

- We are a traditional enterprise that integrates production,research,development and sales, have been deeply involved in the field of welding for nearly 10 years.with domestic and international basis as well as professional certification

Additional information

| Weight | 8.42 kg |

|---|---|

| Dimensions | 43.18 × 36.58 × 28.45 cm |

Reviews

There are no reviews yet.